Phantom occupies a unique place in the history of Rolls-Royce. At any given time during the last 100 years, it has represented the very best in effortless luxury, engineering excellence, fine materials and exquisite, highly skilled craftsmanship. Across eight generations, each as storied as the last, Phantom has remained unrivalled – not just as the marque’s flagship motor car, but the world’s pinnacle luxury product – an icon of icons. As it enters its second century, Phantom remains an authoritative statement of connoisseurship, enjoyed by those who shape our world.

The stories of these individuals – and their motor cars – give Phantom its own place in history. Phantom has been associated with famous people and momentous events from its inception, signifying power and influence through its sheer size, dominant presence and – perhaps most significantly – its unique capacity to reflect its owner’s personality and significance.

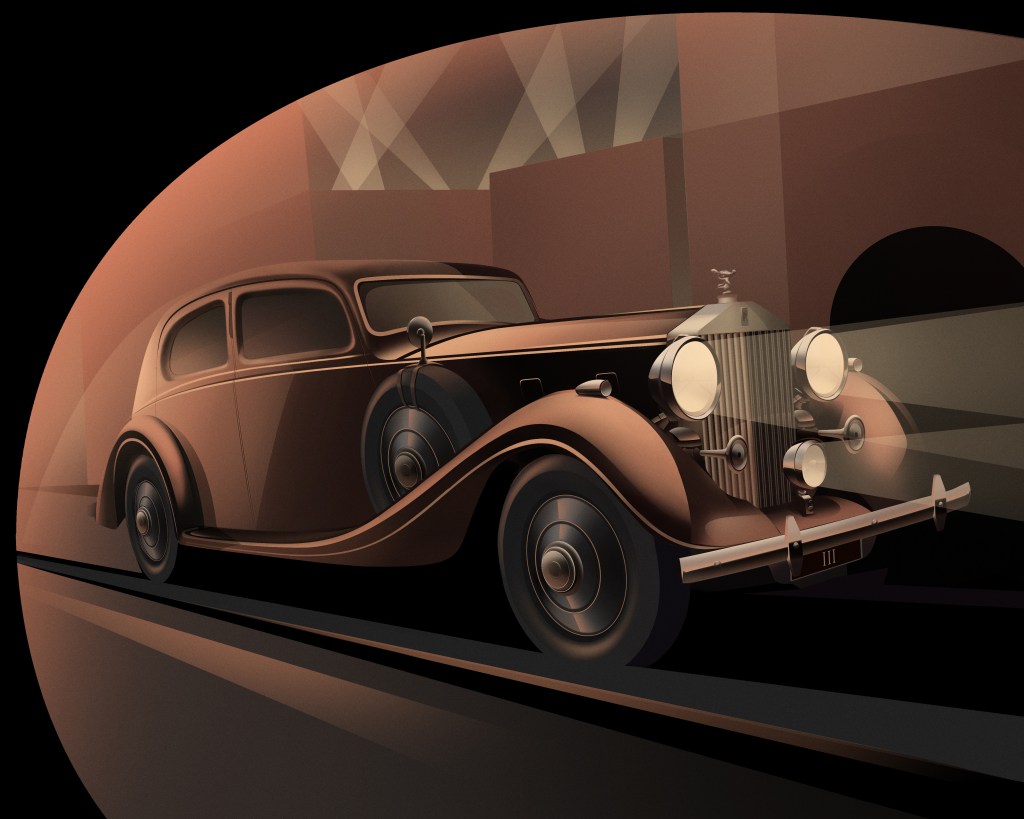

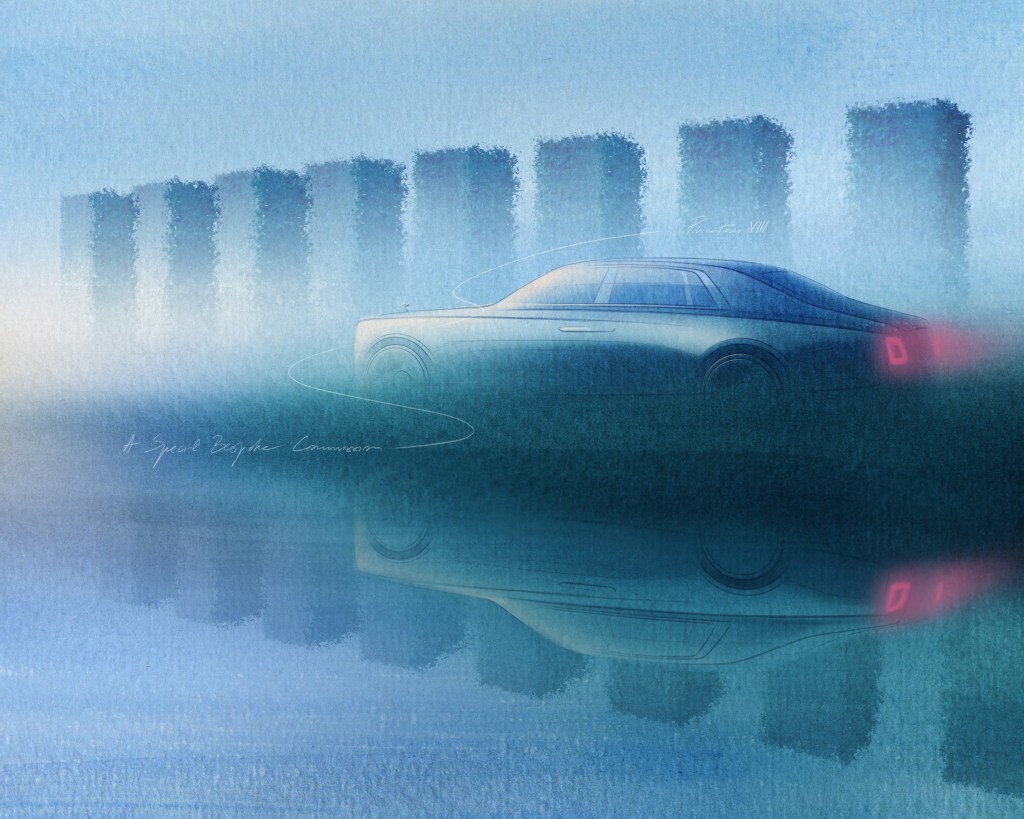

Rolls-Royce marks Phantom’s centenary by reflecting on some of the fascinating stories where Phantom has played a role. The marque’s designers have created a series of original artworks paying tribute to Phantom’s legacy, celebrating this remarkable motor car’s cultural impact through the decades and capturing the spirit of each of its eight generations.

These artworks echo a historical precedent dating back to 1910, when the artist Charles Sykes – who would later create the Spirit of Ecstasy mascot – was commissioned to produce six original oil paintings for the marque’s 80-page catalogue. These images showed Rolls-Royce motor cars arriving at the opera, a country house, the golf course and other venues, reflecting the tastes and lifestyles of its almost exclusively aristocratic owners at the time. The illustrations created by the marque’s designers in 2025 illustrate just how much that client profile has diversified over the past century.

While these contemporary illustrations celebrate Phantom’s evolving role in culture, they also echo a deeper truth: that for a century, Phantom has been present at defining moments in politics, society, and global history. From heads of state to stars of stage and screen, it has served those whose decisions and presence have helped shape the world we live in.

PHANTOM AS A STATEMENT OF AUTHORITY

One of the great commanders of the Second World War, Field Marshal Bernard Law Montgomery, 1st Viscount Montgomery of Alamein, was nicknamed ‘the Spartan General’ for his austere lifestyle. His sole concession to comfort was in his personal transport. Recognising the power of image and symbolism, ‘Monty’ used a pair of Phantoms to communicate permanence, solidity and reliability, sending a clear signal to his troops that he would stick with them through the darkest hours.

Montgomery’s day-to-day transport was a 1936 Phantom III with coachwork by Freestone & Webb, requisitioned from the head of the Talbot Motor Company, Frederick Wilcock. In the build-up to D-Day in June 1944, he used this motor car to convey Winston Churchill, General Eisenhower and even King George VI to planning sessions at the Supreme Headquarters Allied Expeditionary Force in Southwick House, Hampshire.

On occasion, during the war years, he used the ‘Butler’ Phantom III, assigned to the Chief of the Imperial General Staff. This particular motor car was so named because it was originally commissioned for Alan Samuel Butler, Chairman of the De Havilland Aircraft Company. With bodywork by HJ Mulliner, its most distinctive feature was a front-sloping windscreen that made the Phantom 15% more aerodynamic, a quality further enhanced by its swept-tail rear profile and enclosed spare wheel and tyre. Montgomery bought the motor car in 1958 and kept the ‘Butler’ until 1963, during which time it served many eminent passengers including the Prime Ministers of Canada, Australia and New Zealand.

PHANTOM AS THE ROYAL STANDARD

While Montgomery’s Phantoms were present at events that shaped the modern world, others took pride of place in royal households; none more so than in Rolls-Royce’s home of Great Britain.

In 1948, the Duke of Edinburgh, newly married to HRH Princess Elizabeth, paid a visit to Rolls-Royce. He was loaned an experimental car with a newly designed straight-eight 5.3-litre engine nicknamed ‘the Scalded Cat’ by the marque’s test drivers. Shortly after, he asked if the company could create a more formally bodied car for the use of HRH Princess Elizabeth and himself.

The Duke’s request was accepted, and the first Rolls-Royce Phantom IV chassis was laid down. With advice from Rolls-Royce, it was finished to His Royal Highness’ design. The order was confirmed on 15 November, and to preserve secrecy during its creation, it was given the code name Maharajah of Nabha. This historic motor car remains in active service at the Royal Mews under the name Maharajah to this day.

The British Royal Family subsequently commissioned another Phantom IV, two Phantom Vs, and two Phantom VIs to convey the sovereign. One of these is the renowned Silver Jubilee Phantom VI, which was presented to Queen Elizabeth II in 1977 by the British motor industry to celebrate her 25 years on the throne. Famously featuring a Bespoke raised roof, it would be used again in 2011 at the wedding of the then-Duke and Duchess of Cambridge, conveying the bride from the Goring Hotel to Westminster Abbey.

Across continents, another distinguished Phantom V became woven into the legacy of leadership, this time at the dawn of a new nation in the Middle East. Delivered in 1966 with coachwork by Mulliner Park Ward, the motor car was originally commissioned by Sheikh Zayed Bin Sultan Al Nahyan, revered as the ‘founding father’ of the United Arab Emirates. It was present at his inauguration as ruler of Abu Dhabi and played a pivotal role in his unification negotiations with the leaders of Dubai and other neighbouring Emirates. In 1971, this Phantom carried James Treadwell, the first British Ambassador to the UAE, to the ceremony that formally established the federation on 2 December.

Eight years later, that same Phantom V would return to prominence when it served as the official state conveyance for Her Majesty Queen Elizabeth II during her historic visit to the UAE in 1979 – a moment that brought the two royal legacies full circle.

Beyond ceremonial duties, Phantom has long played a quieter role in the theatre of diplomacy. In 1965, the use of Rolls-Royce motor cars by UK government departments was formally debated in Parliament, a reflection of their symbolic weight on the world stage. During this period, Phantom Vs became trusted envoys in themselves, serving British diplomats in postings as far-reaching as New York, Washington, Tokyo and New Delhi, with earlier examples used in Rome and other destinations.

Over the years, Phantom has also been used in official capacities in countries including Australia, Kuwait, Spain, Thailand and the United Arab Emirates – a testament to its role in the subtle language of statecraft. Indeed, the former British ambassador to Paris, Sir John Fretwell, told British newspaper, The Times, “My Rolls certainly helped when visiting the Élysée. The guards on the gate had no excuse for not knowing it was the British ambassador.”

Whether navigating the world stage or serving closer to home, Phantom has always been an imposing presence, as exemplified by Phantom V, launched in 1959 at 5.8m (almost 19ft) long. While no official documentation exists to prove it, some authors have posited that the minimum statutory distance between British parking meters was revised to accommodate its dimensions.

A PHANTOM FOR A BEATLE: ENTER JOHN LENNON

Not every Phantom V was destined for royal service or diplomatic ceremony. Some would come to symbolise an entirely different kind of cultural power. In December 1964, Britain’s disruptor-in-chief, John Lennon, rewarded himself for the success of The Beatles’ A Hard Day’s Night by commissioning his own Rolls-Royce motor car. In typically iconoclastic fashion, Lennon specified his Phantom V should be black everywhere, inside and out. (There are, however, lines that even a Beatle can’t overstep; the motor car’s Pantheon grille and Spirit of Ecstasy mascot retained their conventional bright finish at the marque’s insistence.) This was one of the first cars in Britain to have blacked-out windows, made from darkened, reflective Triplex Deeplight glass.

As Lennon told a Rolling Stone interviewer in 1965, these were not only for privacy, “It’s partly that, but it’s also for when you’re coming home late,” the Beatle remarked. “If it’s daylight when you’re coming home, it’s still dark inside the car – you just shut all the windows and you’re still in the club.”

But this would not be this particular Phantom’s most famous iteration. In May 1967, just days before the release of Sgt. Pepper’s Lonely Hearts Club Band, this motor car was reborn. Inspired by the Romany-style caravan at his home in Weybridge, Lennon reportedly took the advice of Marijke Koger, one of the artists behind the design collective The Fool, and commissioned a complete transformation.

The once-black Phantom was repainted in vibrant yellow and covered with swirling, floral motifs and zodiac symbols. Lennon enlisted a local artist to realise the new design; the result was an artistic manifesto for the Summer of Love the same year, and was often parked proudly outside Lennon’s Kenwood home.

Not everyone approved. As the freshly painted Phantom drove down a promenade in London’s Piccadilly area that summer, Lennon claimed that an outraged Englishwoman shouted, “How dare you do that to a Rolls-Royce!” before attacking the motor car with her umbrella – a moment that only galvanised its legendary status.

Lennon’s Phantom moved with him to New York in 1971, where it became a familiar sight on Manhattan’s Upper West Side. In 1977, he donated it to the Cooper Hewitt Museum. When it was auctioned in 1985, the Phantom sold for $2,299,000 – then a world record for any piece of rock and roll memorabilia. A year later, it was gifted to the Province of British Columbia, where it remains in the care of the Royal British Columbia Museum: a countercultural artefact and perhaps the most famous Rolls-Royce in the world.

The Lennon motor car is just one example of Phantom’s deep ties to the creative industries. Since its inception, Phantom has been the reward of choice for influential figures who have shaped the cultural landscape, both as recognition for their success and as a canvas to express their own personality and vision.

TO HOLLYWOOD AND BEYOND: PHANTOM TAKES THE LEAD

The era of silent movies effectively ended in 1927 with the advent of the ‘talkies’ – feature films with both synchronised recorded music and lip-synchronised singing and speech. Among the pioneers of this transformational art form was the Warner Brothers studio, whose co-founder Jack Warner rewarded himself with a Phantom. While some ‘silent’ stars like Mary Pickford – whose Phantom was famously fitted with a hidden compartment for carrying illicit alcohol in defiance of America’s Prohibition laws – never enjoyed the same success following the advent of synchronised sound, others including Greta Garbo and Fred Astaire effortlessly embraced the new order to become global icons – and, naturally, Phantom I owners.

In the years that followed, Phantom would make numerous appearances on the silver screen. Its annus mirabilis was 1964, in which Phantom took leading roles in two of the year’s major movie releases.

In Goldfinger, the film’s eponymous arch-villain uses his black-and-yellow 1937 Phantom III Sedanca de Ville to smuggle gold over the Furka Pass to his mountain lair, until he is finally thwarted by his nemesis, suave super-spy James Bond. This would be one of 12 appearances by Rolls-Royce motor cars in the long-running 007 franchise. In 2024, the marque commemorated the 60th anniversary of the film’s release with Phantom Goldfinger, a one-of-one Bespoke Phantom VIII, faithfully replicating the original’s distinctive finish and replete with innovative film-inspired details.

The same year also saw the premiere of The Yellow Rolls-Royce, written by legendary British dramatist Terence Rattigan and starring a 1931 Phantom II, with Sedanca de Ville coachwork by Barker. A three-part anthology film, it charts the motor car’s adventures with three different owners – an English aristocrat, a Chicago gangster, and an American socialite – and their lives and loves in the years prior to, and including, the outbreak of the Second World War. The all-star cast featured Rex Harrison, Ingrid Bergman, Shirley MacLaine, Omar Sharif, George C Scott, Alain Delon and Jeanne Moreau; the soundtrack song Forget Domani won a Golden Globe and was later recorded by both Perry Como and Frank Sinatra. The latter would also own a Rolls-Royce.

THE KING’S MOTOR CAR: A PHANTOM FOR ELVIS

Other titans of popular culture naturally gravitated to Phantom as their fame grew across the globe. Elvis Presley, the ‘The King’ himself, loved cars and in 1963 bought his first Phantom V with coachwork by James Young. The suitably rock’n’roll extras included a high fidelity Blaupunkt Köln stereo system, Firestone whitewall tyres, a microphone and a rear armrest containing a writing pad, mirror and clothes brush. It was shipped in Midnight Blue with a grey cloth interior, but in a delightful domestic detail, Elvis had it repainted after his mother’s chickens started pecking at their reflections in the mirror-polish finish. The chosen lighter Silver Blue reportedly didn’t show the blemishes in the paintwork.

In 1968, Elvis donated his Phantom to the SHARE charity – an act which later inspired the song Elvis’s Rolls-Royce by Leonard Cohen and Was (Not Was).

A NEW GENERATION

For decades, Phantom owners tended to fall into two groups: those born into wealth and those who rose to prominence in business, the arts or entertainment. Then, from the mid-1970s, a wave of personal technology began to shift this balance. The arrival of home video, personal computers, mobile phones and eventually the internet, gave individuals the tools to build influence and wealth on their own terms.

A new kind of success story was taking shape. Technology allowed people to make their own fortunes much earlier, and much faster than ever before. It also meant those who already had a public profile – sportspeople, movie stars, musicians and other celebrities – could capitalise on their own image, on their own terms.

This new generation of younger, self-made, entrepreneurial figures was new to luxury. Their tastes were eclectic, individual and unconventional; most importantly, they wanted products that would allow them to express not only their wealth and success, but also their own unique tastes, creative visions and personality.

Phantom VII arrived at the perfect time. As a true Rolls-Royce, it fully met the requirements and expectations of the marque’s traditional clients. But as an entirely new motor car, hand-crafted at the new Home of Rolls-Royce at Goodwood, West Sussex, it was the contemporary product this new generation was looking for. And while it was a complete motor car, it was explicitly positioned as the perfect blank canvas for Bespoke individualisation – just as the coachbuilt Phantoms that preceded it had been.

PHANTOM ENTERS THE SOCIAL MEDIA AGE

For these new owners, Phantom was a motor car in which to be seen; and thanks to social media, they could be – by millions, around the world. In a neat full circle, many of the people who made their fortunes via YouTube and Instagram chose to invest in a Phantom, then used their platforms to share their ownership experience with the world. As its presence grew, Phantom became a fixture at award ceremonies and gala events; in 2012, three special edition Phantom Drophead Coupés made a surprise appearance at the closing ceremony of the London Olympics. The roof of the first retracted to reveal Jessie J, who sang as the motor cars performed laps of the stadium. A suitably grand arrival for such a momentous occasion, this event, along with numerous others in more recent history, was broadcast directly to the devices of millions, making Phantom a social media star in its own right.

PHANTOM TODAY

For 100 years, Phantom has been a quiet but imposing presence in some of history’s most defining and memorable moments. Now in its eighth generation, it remains a potent symbol of power, influence, and success. As well as continuing to attract many of the highest achievers in modern culture, it transcends the automotive world, serving as both the pinnacle of luxury and a cultural icon in its own right.

Whether making cameo appearances in music videos from Calvin ‘Snoop Dogg’ Broadus and Pharrell’s Drop It Like It’s Hot to Drake’s Started From the Bottom, represented in cultural institutions like the Saatchi Gallery and the Serpentine, or serving as a collaborative canvas for brands including Hermès and Iris van Herpen, it continues to reflect and shape the world around it.

Phantom continues to serve as the ultimate canvas for personal expression, facilitating the finest creative hand craftsmanship. Since the dawn of Rolls-Royce’s Goodwood era, it has inspired some of the most extraordinary Bespoke commissions in the marque’s modern age – each a reflection of its commissioning client’s imagination, values and legacy. From intricate expressions of cultural heritage to contemporary works of art, these remarkable motor cars reaffirm Phantom’s position not only as the pinnacle of luxury, but as a medium for self-expression.

As Phantom enters its second century, its journey through culture, communities and continents continues, gathering more momentum than ever. Each new commission adds another chapter to a story still being written – one shaped by the achievements of those who commission it and the timeless commitment to excellence and individuality that have always defined Phantom. In a rapidly changing world, it remains a reassuring constant: the ultimate expression of presence, purpose and personal legacy.

Chris Brownridge, Chief Executive, Rolls-Royce Motor Cars, said: “Phantom is much more than a motor car. For 100 years, it has stood at the pinnacle of all Rolls-Royce motor cars – a cultural phenomenon that both reflects and influences the world around it. From its earliest days, Phantom has been one of the most desired rewards for success and a potent symbol of power and prestige on the world stage. Beyond status, it has always offered its owners a canvas for personal expression, transformed through Bespoke craftsmanship into a moving work of art. Across music, politics, art and beyond, Phantom has been present at many of history’s defining moments. The stories that surround it – and the images they’ve inspired our designers to create – reveal its extraordinary reach, and its enduring connection to greatness.”